How to Hire the Right Woodchipper for Commercial Jobs: The Complete Guide for Groundcare Professionals

Choosing the right woodchipper is essential for any commercial groundcare business, arborist, or estate manager who needs to process woody material efficiently and safely.

In this guide, we explain everything you need to know to choose the best woodchipper for your commercial jobs, whether you work in landscaping, tree surgery, contracting, estate management, or local authority Groundcare.

Why Choosing the Correct Commercial Woodchipper Matters

Woodchippers vary massively in capacity, performance, feed system, and build quality. Selecting a model that doesn’t match the type of work you do can lead to:

-

-

Frequent machine jams

-

Slow or uneven output

-

Higher fuel consumption

-

Excessive wear on blades and bearings

-

Increased maintenance and unexpected downtime

-

However, get it right and you can dramatically boost output, reduce labour costs and get consistent performance and safer operations.

Key Factors to Consider When Choosing a Woodchipper

1. Maximum Branch Diameter and Material Type

The first question to ask is: What size wood do you process most often?

Commercial models typically range from 4-inch to 12-inch capacity. Always choose a machine with slightly more capacity than your typical workload to avoid overloading.

-

-

-

- Light maintenance and pruning: 3–6 inch capacity

- Mixed branch work and regular tree care: 6–8 inch

- Heavy-duty arborist or site clearance work: 8–12 inch

-

-

On our hire fleet we offer the Jo Beau at 3”, Forst at 6” and our Greenmech tracked at 8”.

If you handle forked, twisted, leafy, or irregular branches, choose a chipper with a larger infeed throat and more aggressive feed system.

2. Disc vs Drum Woodchipper — Which Is Better?

Understanding the difference between disc chippers and drum chippers is key to choosing the right machine.

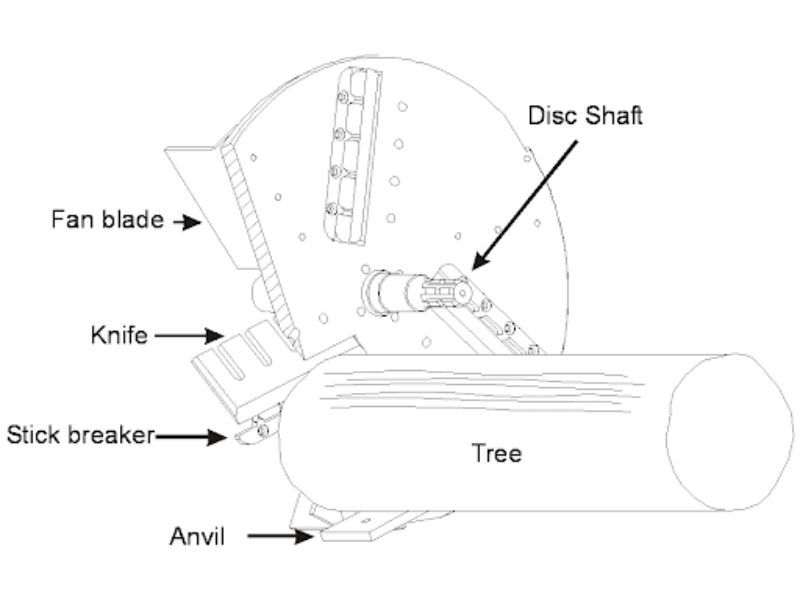

Disc Chippers

-

-

-

- Use a rotating steel flywheel with 3 knives

- Produce more uniform, cleaner chips

- Typically more fuel-efficient for small–medium material

- Great for landscaping, mulch production, and tidy commercial sites

-

-

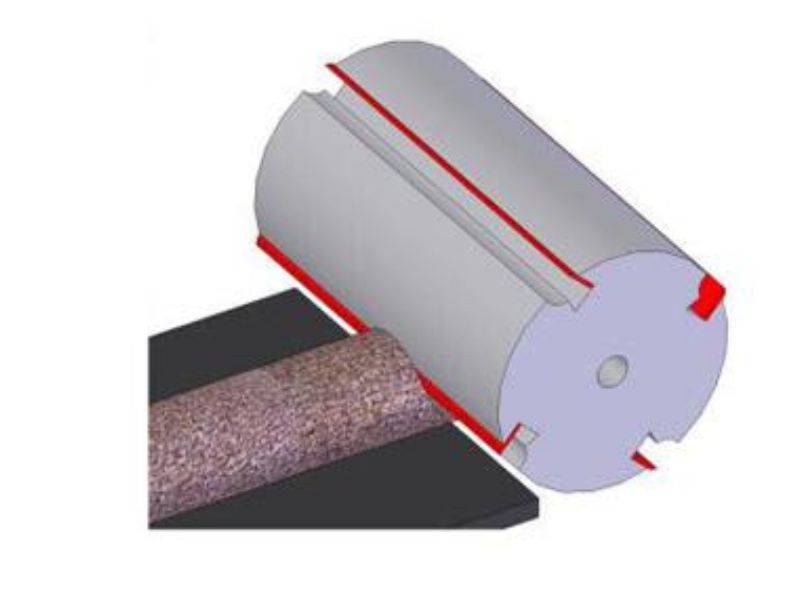

Drum Chippers

-

-

-

- Use a horizontal rotating drum for aggressive pulling power

- Handle larger logs, mixed brush, and twisted branches with ease

- Better for high-volume or heavy-duty commercial tasks

- Ideal for arborists, woodland work, and site clearance

- flat knives mounted to a rotating disc (flywheel), cutting wood cleanly against a fixed anvil.

-

-

Flat Knife Chippers

-

-

-

- Uses flat knives mounted to a flywheel, cutting wood against a fixed anvil.

- Produces a higher quality and more consistent set of chips.

- Most effective on straight and clean branches.

- Good for arborists, woodland work, site clearance.

-

-

If chip quality matters → choose a flat knife chipper.

If throughput and versatility matter → choose a drum chipper.

We offer a range of the more popular disc chippers for hire.

Jo Beau M300 Chipper

Forst ST6P 6" Towable Chipper

1. Maximum Branch Diameter and Material Type

The first question to ask is: What size wood do you process most often?

Commercial models typically range from 4-inch to 12-inch capacity. Always choose a machine with slightly more capacity than your typical workload to avoid overloading.

-

-

-

- Light maintenance and pruning: 3–6 inch capacity

- Mixed branch work and regular tree care: 6–8 inch

- Heavy-duty arborist or site clearance work: 8–12 inch

-

-

On our hire fleet we offer the Jo Beau at 3”, Forst at 6” and our Greenmech tracked at 8”

If you handle forked, twisted, leafy, or irregular branches, choose a chipper with a larger infeed throat and more aggressive feed system.

Jo Beau M300 Chipper

Forst ST6P 6" Towable Chipper

2. Disc vs Drum Woodchipper — Which Is Better?

Understanding the difference between disc chippers and drum chippers is key to choosing the right machine.

Disc Chippers

-

-

-

- Use a rotating steel flywheel with knives

- Produce more uniform, cleaner chips

- Typically more fuel-efficient for small–medium material

- Great for landscaping, mulch production, and tidy commercial sites

-

-

Drum Chippers

-

-

-

- Use a horizontal rotating drum for aggressive pulling power

- Handle larger logs, mixed brush, and twisted branches with ease

- Better for high-volume or heavy-duty commercial tasks

- Ideal for arborists, woodland work, and site clearance

-

-

If chip quality matters → choose a disc chipper.

If throughput and versatility matter → choose a drum chipper.

We offer a range of the more popular disc chippers for hire.

Flat Blade Woodchipper

Credit: Wood Energy IE

Drum Woodchipper

Credit: Gemco Energy

3. Power Source and Feed Mechanism

Power Source

Commercial woodchippers are typically:

-

-

-

- Petrol or diesel-powered for mobile contractor use

- PTO-driven for estates or farms with tractors

- Electric chippers exist but are rarely suitable for heavy commercial work

-

-

Diesel engines generally offer more torque for larger material.

You can find both diesel and petrol options in our hire fleet.

3. Power Source and Feed Mechanism

Power Source

Commercial woodchippers are typically:

-

-

-

- Petrol or diesel-powered for mobile contractor use

- PTO-driven for estates or farms with tractors

- Electric chippers exist but are rarely suitable for heavy commercial work

-

-

Diesel engines generally offer more torque for larger material.

You can find both diesel and petrol options in our hire fleet.

Feed System

For commercial work, hydraulic or self-feeding systems are essential.

Manual-feed machines slow operators down, increase fatigue, and raise safety risks.

We offer a range including the Jo Beau for manual feed and our larger Forst and Greenmech chippers are hydraulic feed.

4. Mobility, Transport and Site Access

Think about the environments you work in:

-

-

-

- Towable chippers are ideal for contractors moving between sites

- Tracked chippers are preferred for forestry, banks, and awkward terrain

- Compact chippers work well in estates, cemeteries, parks, and tight access jobs

-

-

Also consider towing weights, storage space, and manoeuvrability.

You can find both towable and tracked chippers on our hire fleet.

5. Quality of Output (Chip Size and Consistency)

What will you do with the chips?

-

-

-

- For mulch, biomass, or decorative use, choose a machine known for consistent chip size (usually flat knife chippers).

- For waste disposal or volume reduction, chip size is less important — a drum chipper’s throughput is more valuable.

-

-

We offer the more popular disc chippers only.

Hiring is a great option to avoid tying up capital. Our machines are thoroughly checked and blades sharped regularly to keep them hire-ready. You will always have the right machine for the job, and we offer the convenience of delivery to site and no maintenance or repair costs.😊

Greenmech 19/28 Tracked Chipper

Choosing the Right Woodchipper for Your Type of Work

Use | Type of Work | Best Choice | Why |

|---|---|---|---|

Light Commercial Grounds Maintenance | Hedge trimming, shrub pruning, small tree maintenance |

| Clean, consistent chipping and excellent for regular, tidy maintenance jobs. |

General Commercial Landscaping and Mixed Estates Work | Branches, mixed brush, seasonal pruning |

| Versatile enough for varied workloads across parks, campuses, schools, retail parks, and housing estates. |

Professional Arborists and Tree Surgeons | Large limbs, mixed timber, awkward branches | 7–9" hydraulic-feed drum chipper | Powerful, fast, reliable for daily tree surgery workloads. |

Forestry, Large Estates and Site Clearance | High-volume timber, storm debris, logs, heavy branches |

| Maximum throughput and rugged performance for demanding jobs. |

Use | Type of Work | Best Choice | Why |

|---|---|---|---|

Light Commercial Grounds Maintenance | Hedge trimming, shrub pruning, small tree maintenance |

| Clean, consistent chipping and excellent for regular, tidy maintenance jobs. |

General Commercial Landscaping and Mixed Estates Work | Branches, mixed brush, seasonal pruning |

| Versatile enough for varied workloads across parks, campuses, schools, retail parks, and housing estates. |

Professional Arborists and Tree Surgeons | Large limbs, mixed timber, awkward branches | 7–9" hydraulic-feed drum chipper | Powerful, fast, reliable for daily tree surgery workloads. |

Forestry, Large Estates and Site Clearance | High-volume timber, storm debris, logs, heavy branches |

| Maximum throughput and rugged performance for demanding jobs. |

In Summary

Hiring the right woodchipper can transform the productivity of a commercial groundcare team — whether you’re a contractor, arborist, estate manager or local authority.

Matching chipper type, capacity and feed system to your workload is the key to reliability and efficiency, and here at Acacia Groundcare our friendly team are always on hand to give you advice in order to save you any costly mistakes.